Your One-stop Solution for Precision Investment Castings

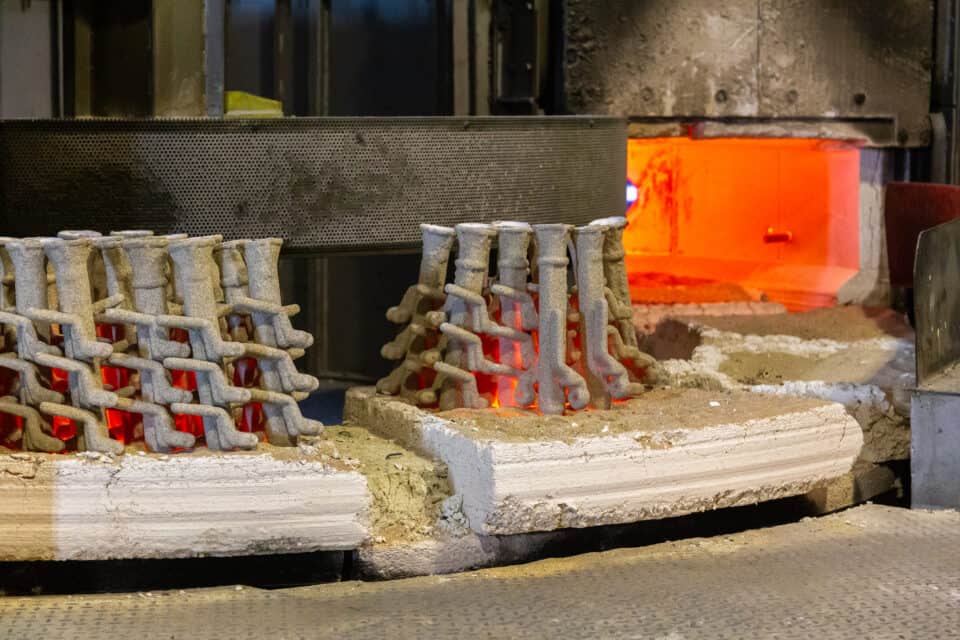

As an established investment casting specialist with 13+ years of expertise, Kellyder offers unrivaled quality, value, and delivery performance. Our full-service capabilities include design support, prototype development, precision wax tooling, ceramic shell building, vacuum melting, casting, finishing, and inventory management – all under one roof. This enables complete production control to optimize cost, quality, and lead times.

24h

Quick Quote±0.01

mm Tolerance30

days Mold Manufacturing20%

Purchase Cost Savings

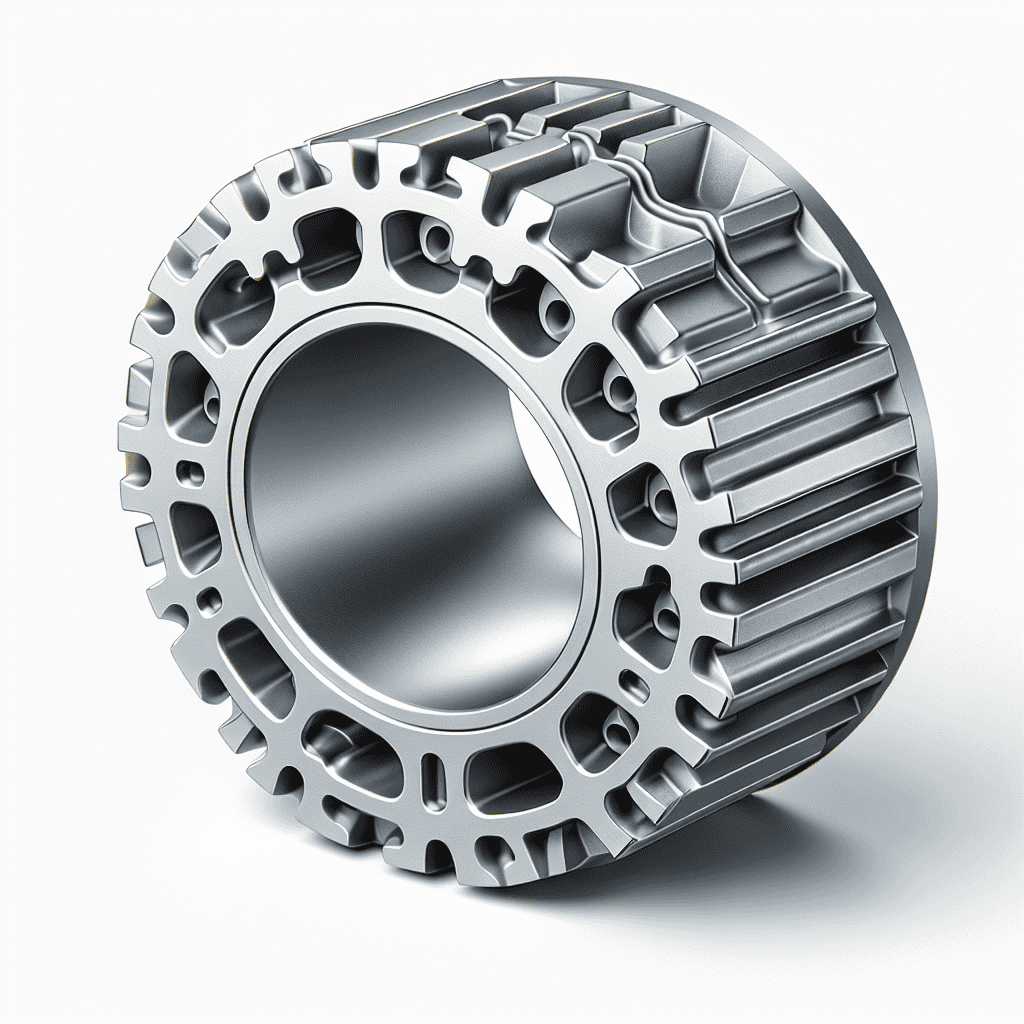

Investment Casting Process

Service Features

Customized for Your Application

We specialize in providing exceptional quality castings at economical pricing coupled with best-in-class customer service and technical support.

Uncompromising Quality

Certified for ISO 9001 standard, we perform over 25 stringent checks including X-ray and multi-layer FPI testing achieving <1% defect rate for 15,000+ castings annually.

Save 20% with Our Pricing

High production capacity of 500 tons/annum coupled with efficient in-house sand reclamation, preform automation etc ensures >20% cost savings compared to market without quality compromise.

Premium Customer Experience

Our team with >15 years cumulative expertise provides technical hand-holding through design, engineering changes, rightsizing material choices etc. to provide delight.

Get in Touch with Our Experts

- Respond to the request within 2 hours

- 30 days to complete the mold

- Sample production in 7 days

All uploads are secure and confidential

Precision Investment Castings in Exotic Materials

- Stainless Steel

- Al, Mg and Cu Alloys

- Stainless Steel

- Al, Mg and Cu Alloys

- none

Precision Finishing Processes for Investment Castings

Investment Casting Finishes

Kellyder offers a wide array of finishing processes to enhance aesthetic appearance, improve functional performance, or achieve critical dimensions on stainless steel and exotic alloy precision investment castings.

| Name | Description |

|---|---|

| As-Cast Finish | The as-cast condition directly out of the ceramic shell mold offers a cost-effective option when surface properties can be utilized as is. Minimal manual grinding/deburring provided. |

| Abrasive Finishing | Uniform abrasive finishing like barrel tumbling or as-required spot grinding/linishing provided to offer enhanced flatness and improved cosmetic appearance. |

| Polishing | Manual or automated buffing/polishing provided to obtain soft satin matte textures or brighter polished finishes - ranging from brushed to high gloss mirrors. Great for decorative components. |

| Metallic Coatings | Functional metallic coatings including nickel, copper, zinc and precious metal plating provided to enhance corrosion resistance, electrical conductivity, solderability or other surface properties. |

| Paint and Dry Film Coatings | Polymer coatings including powder coating, epoxy, polyurethane, silicone etc can be applied on investment castings to obtain thickness, chemical, wear and UV resistance properties. Aesthetic colors/effects. |

| CNC Machining | Precision CNC milling, turning, drilling and other machining processes provided either for critical dimensions not achievable in casting or for enhanced surface finish requirements. Hole tolerances within 0.02mm demonstrated. |

Get a Free Instant Quote

We will respond quickly to your needs within two hours and instantly customize a solution for you based on the information and drawings you provide.

Get Free Quote

Applications of Inveatment Casting

Serving Mission-Critical Applications Across Industries

Leveraging stringent process control and certified exotic materials, Kellyder specializes in small to medium sized precision investment steel castings for critical applications across automotive, aerospace, medical.

Advantages and Disadvantages

Leveraging the Unique Benefits of Investment Casting

Investment casting offers unrivaled design flexibility, accuracy, and material properties by eliminating draft angles and parting lines. However, higher initial tooling costs can constrain economical batch sizes.

Your Growth Partner in Investment Casting

Why Choose Us

Join numerous global OEMs and leading manufacturers who rely on our specialized large scale foundry for precision metal casting across sectors.

Repeatable Precision

Capability to accurately reproduce specifications time after time combined with exceptional process control and wildly ISO-certified quality management.

Expert Service Guidance

Our rich cross-industry experience empowers us to hand-hold you during product design and choice of materials or alloys to optimize functionality, yield and outcomes.

Complete Ownership

Hassle-free outsourcing as we undertake complete responsibility across the full casting production cycle, keeping you informed and updated throughout the process.

Trust and Reliability

Long-standing vendor partnerships with leading industrial OEMs demonstrates customer trust in our resilience to handle critical delivery schedules.

Answers to Common Questions

Below we address some of the frequent doubts about capabilities, process limitations, timeframes etc from global customers exploring precision investment casting services for their components.

What Are Your Standard Delivery Timeframes?

What Design Tolerances Do You Maintain?

What Are The Size and Weight Limitations?

Which File Formats Do You Accept?

What Alloys Cannot Be Investment Cast?

What Post-Casting Services Do You Offer?

Get a Free Instant Quote Now

Contact Us Today

Our experts are online 24h, will respond quickly within two hours of receiving your demand, and immediately customize personalized one-stop solutions for you according to the information and drawings you provide.