Custom Metal Parts for the Automotive Industry

Leveraging 11+ years of manufacturing expertise to produce high-quality prototypes and production parts for leading automotive OEMs and Tier 1 suppliers.

Why Choose Us

Why Automotive Companies Trust Kellyder

We bring extensive capabilities and proven expertise for prototyping and volume production of intricate, tight-tolerance automotive parts.

One-Stop Customized Solutions

Beyond manufacturing parts to print, we offer value-added services tailored to automotive needs - from design and testing support to supply chain optimization and inventory management. Our collaboration helps clients tackle industry challenges.

Efficient Logistics for On-Time Delivery

We understand automotive production relies on just-in-time delivery. Through optimized production planning, packaging, and shipment arrangements, we consistently meet supplier and OEM delivery windows, ensuring no line stoppages.

Stringent Quality Assurance

Our comprehensive quality control procedures, covering inspection and testing at every stage from materials and tooling to final components, ensure manufactured parts meet dimensional, material, and performance specifications per automotive standards.

Streamlined End-to-End Solution Process

We guide customers through a structured process spanning concept validation to eventual mass production with quality ingrained at all steps.

In-Depth Product Concept Investigation

Initial collaborations with extensive discussions to share new product visions and explore unconventional concepts. Comprehensive analysis spanning technical viability, manufacturability assessments, regulatory compliance, target costs, timing constraints etc. Definition of key metrics on critical factors like safety, functionality, environmental impact. Decision on whether to invest in further development or return to drawing board.

Design Iteration Leveraging Prototyping and Simulation

Create multiple generations of prototypes and digital models while continuously refining and rigorously analyzing the design performance to validate specs and identify improvements. Harness emerging technologies like generative design, 3D printing and rapid tooling to accelerate learning. Conduct simulations across factors like structural integrity, manufacturability etc. Achieve design freeze when all metrics are fully met.

Production System and Process Optimization

Deep collaboration across design, manufacturing, quality teams etc. to optimize materials, processes, tooling, quality systems, controls etc. to support reliable mass production. Conducting comprehensive capability and reliability assessments spanning functionality, durability, manufacturability etc. Stress testing through over engineered prototypes. Obtaining most stringent automotive approvals and certifications related to performance, safety etc.

Seamless Production Launch and Ongoing Improvements

Ensuring glitch-free production launch through cross-functional pilot builds and testing. Flawless execution of mass production with more stringent QC practices than industry norms. Seeking sustained improvements in quality, cost, delivery and flexibility through rigorous Kaizen methodologies. Updating control plans and work instructions in managed phases according to automotive change management processes. Exploring emerging sustainability initiatives w.r.t energy, emissions etc.

Our Manufacturing Capabilities

Leverage our full spectrum of metalworking capabilities to produce high-quality automotive parts and components.

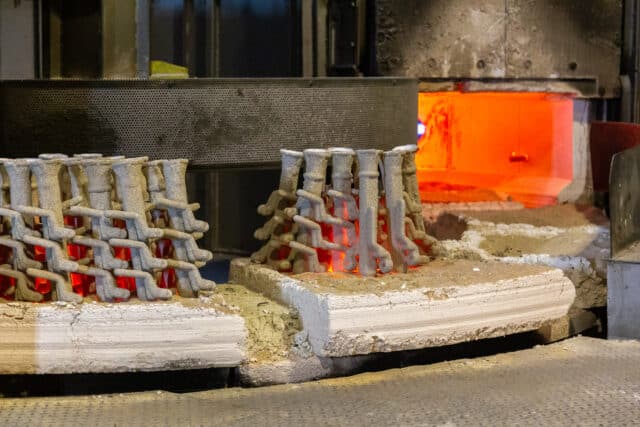

Investment Casting

acilitates intricate, net-shape metal components like turbocharger housings, valves, train parts etc. to precision tolerances.

Send Your Request to Our Experts

Get in touch with our experts to analyze your project and customize an exclusive solution.

Send Email

Optimal Materials for Auto Components

- Aluminum Alloys

- Magnesium & Titanium Alloys

- Aluminum Alloys

- Magnesium & Titanium Alloys

Surface Treatment

| Image | Name | Description |

|

|

Anodizing | We perform both decorative and hard anodizing on aluminum parts to achieve tailored optical properties plus increased hardness, abrasion resistance and corrosion protection meeting automotive needs. |

|

|

Powder Coating | Our automated powder coating facilities provide high consistency in achieving desired color, gloss, texture and coating thickness. This also protects against corrosion, chemicals and mechanical impacts. |

|

|

Plating | We offer high quality electroplated coatings including zinc, nickel, copper, chromium and more with functional benefits like wear protection besides aesthetics. Has important uses in connectors. |

|

|

PVD Coatings | For specialized applications like gearbox components, we employ high hardness, low-friction ceramic coatings of titanium nitride (TiN), zirconium nitride (ZrN) and others using physical vapor deposition. |

|

|

Painting | Where needed, we customize cross-functional compatible multi-layer painting for excellent color consistency, luster and extended durability to environmental factors. |

|

|

Passivation | For stainless steel automotive parts, passivation improves corrosion resistance through the formation of a protective surface layer rich in chromium oxides. We offer citric and nitric acid passivation processes. |

.wpDataTables.wpDataTablesWrapper.wdtVerticalScroll { overflow-y:auto; height:600px; }

.wpDataTableContainerSimpleTable .wdt-res-wrapper.active {overflow: initial; max-height:600px !important; }

.wpdt-fs-000018 { font-size: 18px !important;}

.wpdt-bc-201A16 { background-color: #201A16 !important;}

.wpdt-tc-DB3A31 { color: #DB3A31 !important;}

.wpdt-fs-000014 { font-size: 14px !important;}

/* th background color */

.wpdt-c.wpDataTablesWrapper table.wpdtSimpleTable.bt[data-has-header=’1′] td.wpdt-header-classes,

.wpdt-c.wpDataTablesWrapper table.wpdtSimpleTable thead th,

.wpdt-c .wpDataTablesWrapper table.wpDataTable thead th,

.wpdt-c .wpDataTablesWrapper table.wpDataTable thead th.sorting {

background-color: #000000 !important;

background-image: none !important;

}

| Name | Description |

|---|---|

| Anodizing | We perform both decorative and hard anodizing on aluminum parts to achieve tailored optical properties plus increased hardness, abrasion resistance and corrosion protection meeting automotive needs. |

| Powder Coating | Our automated powder coating facilities provide high consistency in achieving desired color, gloss, texture and coating thickness. This also protects against corrosion, chemicals and mechanical impacts. |

| Plating | We offer high quality electroplated coatings including zinc, nickel, copper, chromium and more with functional benefits like wear protection besides aesthetics. Has important uses in connectors. |

| PVD Coatings | For specialized applications like gearbox components, we employ high hardness, low-friction ceramic coatings of titanium nitride (TiN), zirconium nitride (ZrN) and others using physical vapor deposition. |

| Painting | Where needed, we customize cross-functional compatible multi-layer painting for excellent color consistency, luster and extended durability to environmental factors. |

| Passivation | For stainless steel automotive parts, passivation improves corrosion resistance through the formation of a protective surface layer rich in chromium oxides. We offer citric and nitric acid passivation processes. |

Key Automotive Parts We Produce

We offer specialized capabilities targeted for these critical auto components.

Turbochargers

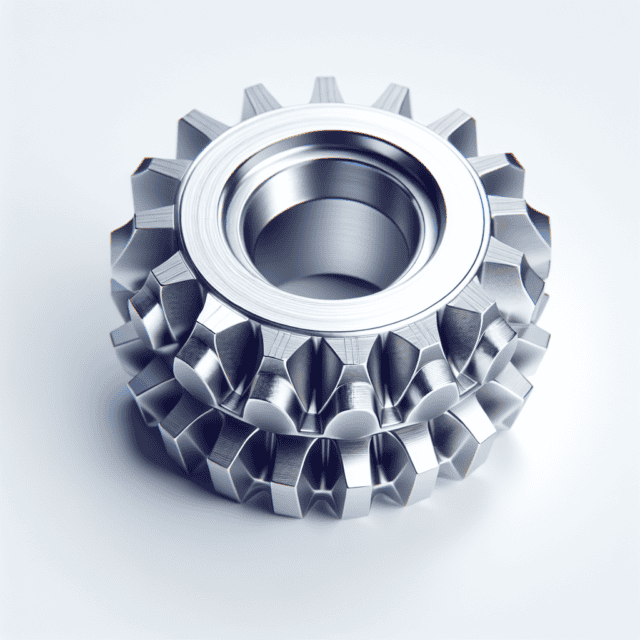

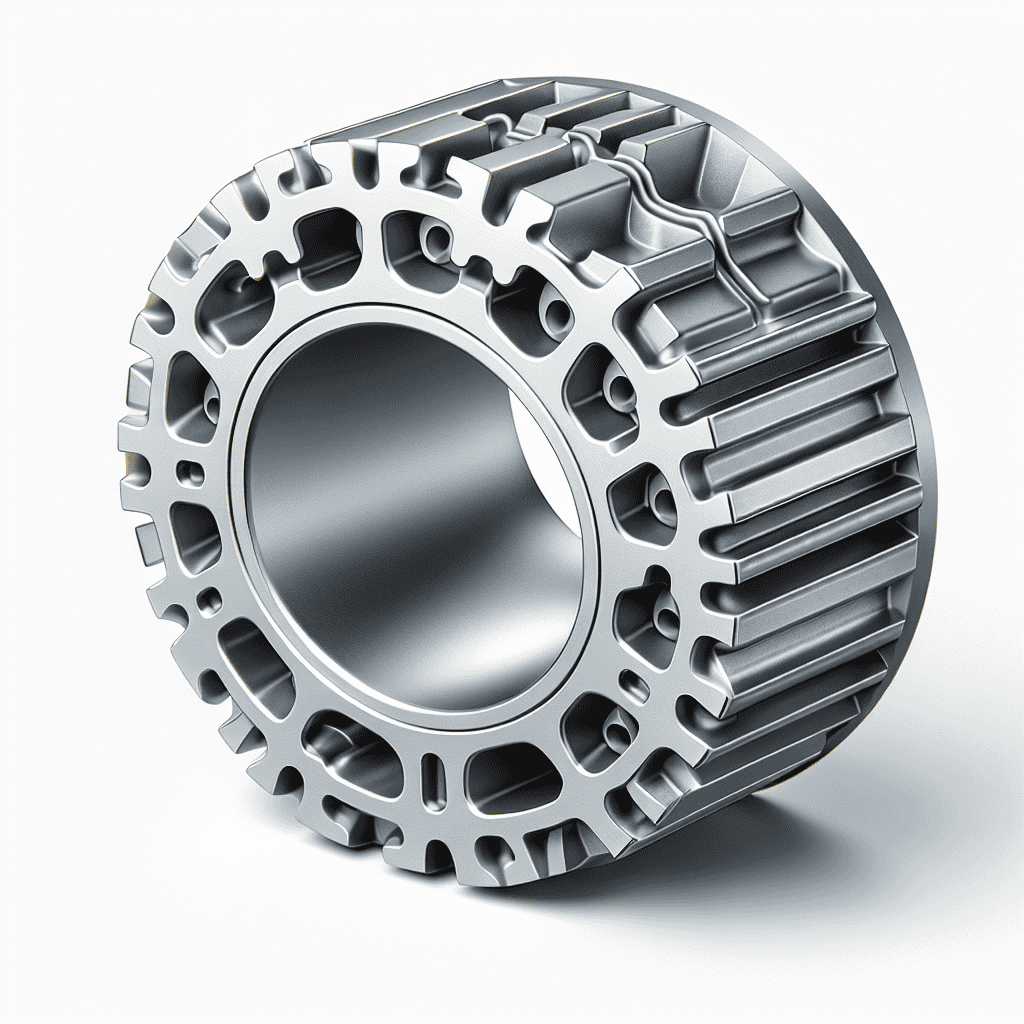

Transmission Components

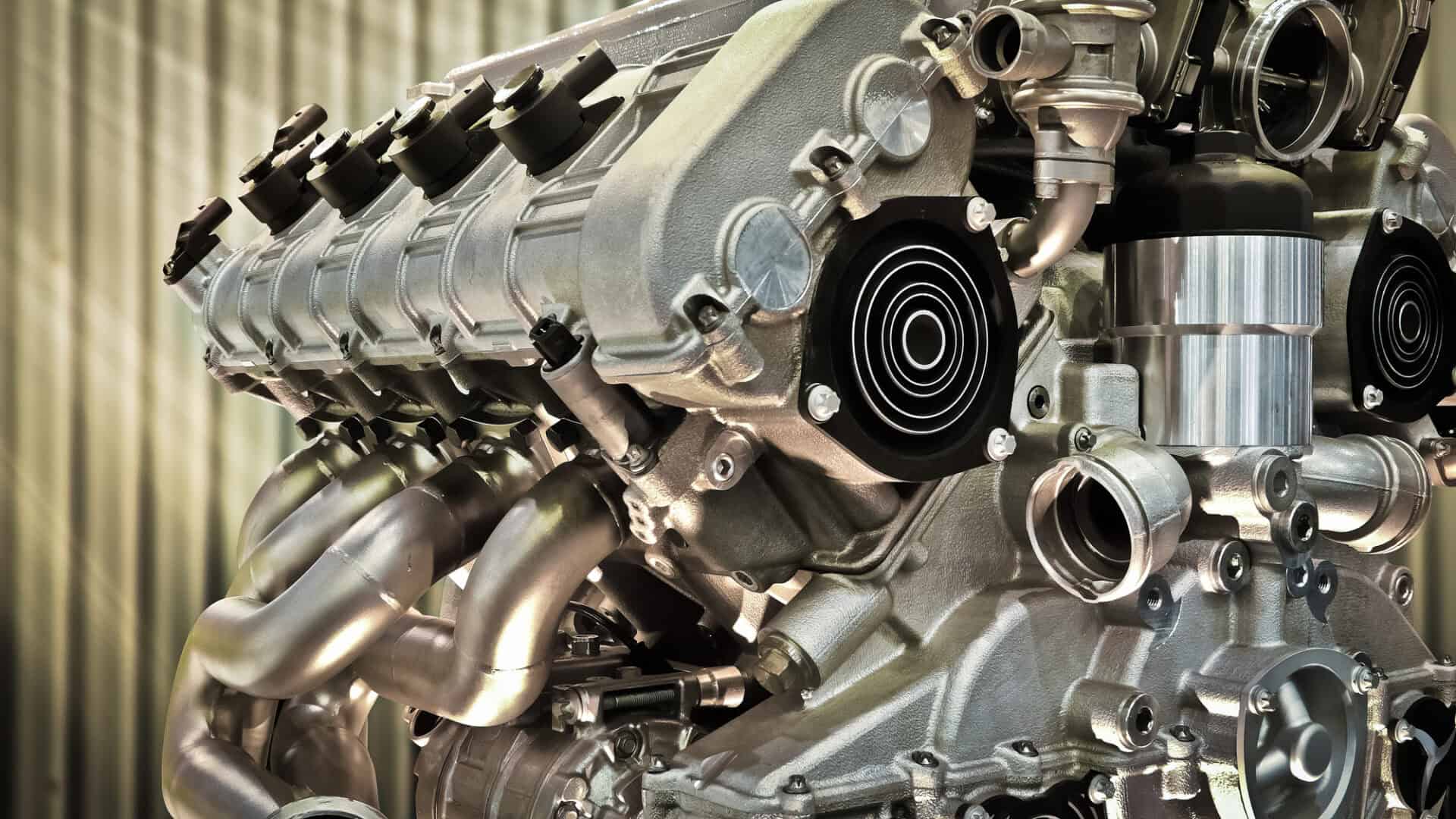

Engine/Powertrain Parts

accent heading

Call to action heading

- A great selling point goes here

- A great selling point goes here

- A great selling point goes here

These are the terms of the opt-in form.

Explore Our Automotive Portfolio

Product Showcase

See firsthand the complex automotive components and end-use products we have manufactured.

Serving Multiple Essential Industries

Kellyder Supports Applications

Kellyder provides specialized manufacturing services across.

Aerospace

We produce intricate aircraft engine cases, structural airframe components, landing gear parts, ground support equipment and more to exacting industry standards. Vacuum casting and HIPping play a key role.

Construction

Leveraging expertise on robust design, we manufacture heavy equipment components including powertrain parts, hydraulics, attachments, undercarriages etc. for reliability in punishing operating conditions.

Industrial

Ranging from minute robotic end-effector components to large die cast tooling inserts to plastic injection molds, we craft complex machined & cast parts that shape final products.

Medical Devices

We offer specialized investment casting, machining and finishing capabilities for hip/knee implants, surgical instruments featuring biocompatible alloys fulfilling stringent medical device protocols.

Guides on Manufacturing

Access more information on our manufacturing capabilities through white papers, ebooks and blog posts.

Get a Free Instant Quote Now

Contact Us Today

Our experts are online 24h, will respond quickly within two hours of receiving your demand, and immediately customize personalized one-stop solutions for you according to the information and drawings you provide.