Custom Metal Parts for the Construction Industry

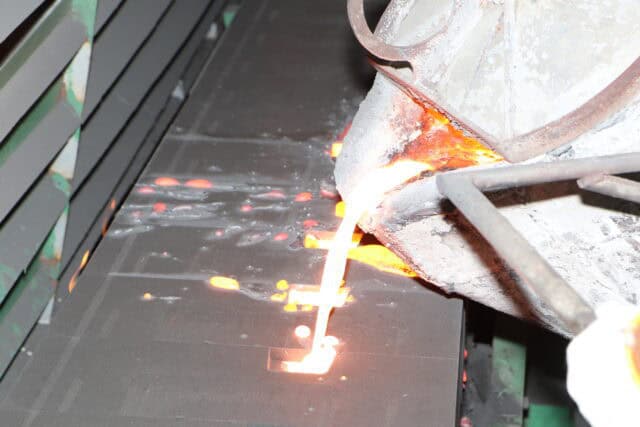

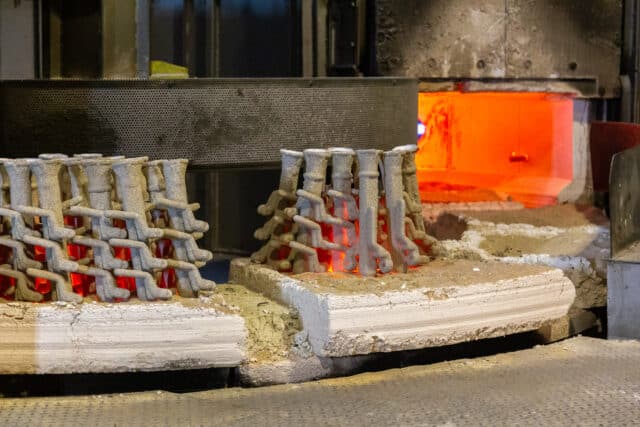

Kellyder specializes in providing customized metal prototypes, parts and components for the construction sector. With our in-house sand casting, investment casting, die casting and CNC machining capabilities, we can deliver high-quality solutions catered to your specific requirements.

Why Choose Kellyder

A Reliable One-Stop Solution

With over 10 years of experience serving the construction industry, we have the expertise and production capabilities to handle your project efficiently.

Comprehensive Production Process

From prototyping to mass production, we provide a streamlined solution covering processes like sand casting, investment casting, die casting, CNC machining, finishing, surface treatments etc.

Stringent Quality Control

Our quality management system ensures dimensional accuracy and surface finish as per your specifications. Real-time monitoring at each process stage gives you complete visibility.

Quick Turnaround Time

With our production capacity and expertise, we are able to complete mold manufacturing in 30-35 days, sample manufacturing in 7 days and 2000-5000 sets of products in 20-30 days.

Seamless Progression From Prototype to Production

We follow a well-defined 4-stage process allowing smooth transition from prototype creation to volume production while ensuring continuous client involvement for transparency and alignment at every phase.

Design Review and Finalization

Rapid Concept Validation through Prototyping

Streamlined Volume Manufacturing

Metalworking Equipment for Diverse Applications

Our extensive machinery portfolio enables manufacturing small batches of intricate prototypes to volume production of large metal parts for varied construction needs.

Send Your Request to Our Experts

Get in touch with our experts to analyze your project and customize an exclusive solution.

Send Email

Optimal Materials to Withstand Demanding Conditions

- Stainless Steels

- Aluminum/Zinc Alloys

- Stainless Steels

- Aluminum/Zinc Alloys

Enhancing Durability, Appearance and Performance

| Image | Name | Description |

|

|

Anodizing | Anodizing creates a thick oxide layer on aluminum components, enhancing corrosion & abrasion resistance. Different anodizing types suit different environments. |

|

|

Powder Coating | We apply durable and attractive powder coatings to metal parts after suitable pre-treatment. This improves aesthetic appeal and protects against corrosion. |

|

|

Electroplating | Electroplating deposits a metallic coating like zinc, nickel, chrome etc. onto metal components to enhance specific properties. |

|

|

Phosphating | Phosphating applies protective phosphate coatings on metal components, acting as an excellent paint base besides improving wear resistance. |

|

|

Passivation | We provide passivation (oxide layer formation) surface treatment for stainless steel components, boosting corrosion resistance. |

|

|

Sand Blasting | Our sand blasting process smoothens surfaces and facilitates painting by creating an anchor pattern through controlled abrasion. |

.wpDataTables.wpDataTablesWrapper.wdtVerticalScroll { overflow-y:auto; height:600px; }

.wpDataTableContainerSimpleTable .wdt-res-wrapper.active {overflow: initial; max-height:600px !important; }

.wpdt-fs-000018 { font-size: 18px !important;}

.wpdt-fs-000014 { font-size: 14px !important;}

/* th background color */

.wpdt-c.wpDataTablesWrapper table.wpdtSimpleTable.bt[data-has-header=’1′] td.wpdt-header-classes,

.wpdt-c.wpDataTablesWrapper table.wpdtSimpleTable thead th,

.wpdt-c .wpDataTablesWrapper table.wpDataTable thead th,

.wpdt-c .wpDataTablesWrapper table.wpDataTable thead th.sorting {

background-color: #000000 !important;

background-image: none !important;

}

| Name | Description |

|---|---|

| Anodizing | Anodizing creates a thick oxide layer on aluminum components, enhancing corrosion & abrasion resistance. Different anodizing types suit different environments. |

| Powder Coating | We apply durable and attractive powder coatings to metal parts after suitable pre-treatment. This improves aesthetic appeal and protects against corrosion. |

| Electroplating | Electroplating deposits a metallic coating like zinc, nickel, chrome etc. onto metal components to enhance specific properties. |

| Phosphating | Phosphating applies protective phosphate coatings on metal components, acting as an excellent paint base besides improving wear resistance. |

| Passivation | We provide passivation (oxide layer formation) surface treatment for stainless steel components, boosting corrosion resistance. |

| Sand Blasting | Our sand blasting process smoothens surfaces and facilitates painting by creating an anchor pattern through controlled abrasion. |

Metal Parts and Components for All Construction Needs

Kellyder serves broad construction sector requirements - from structural elements to heavy equipment components and more.

The operation of CNC milling machine .The CNC milling machine chamfering the mold part with chamfer tool . Excavators and Loaders

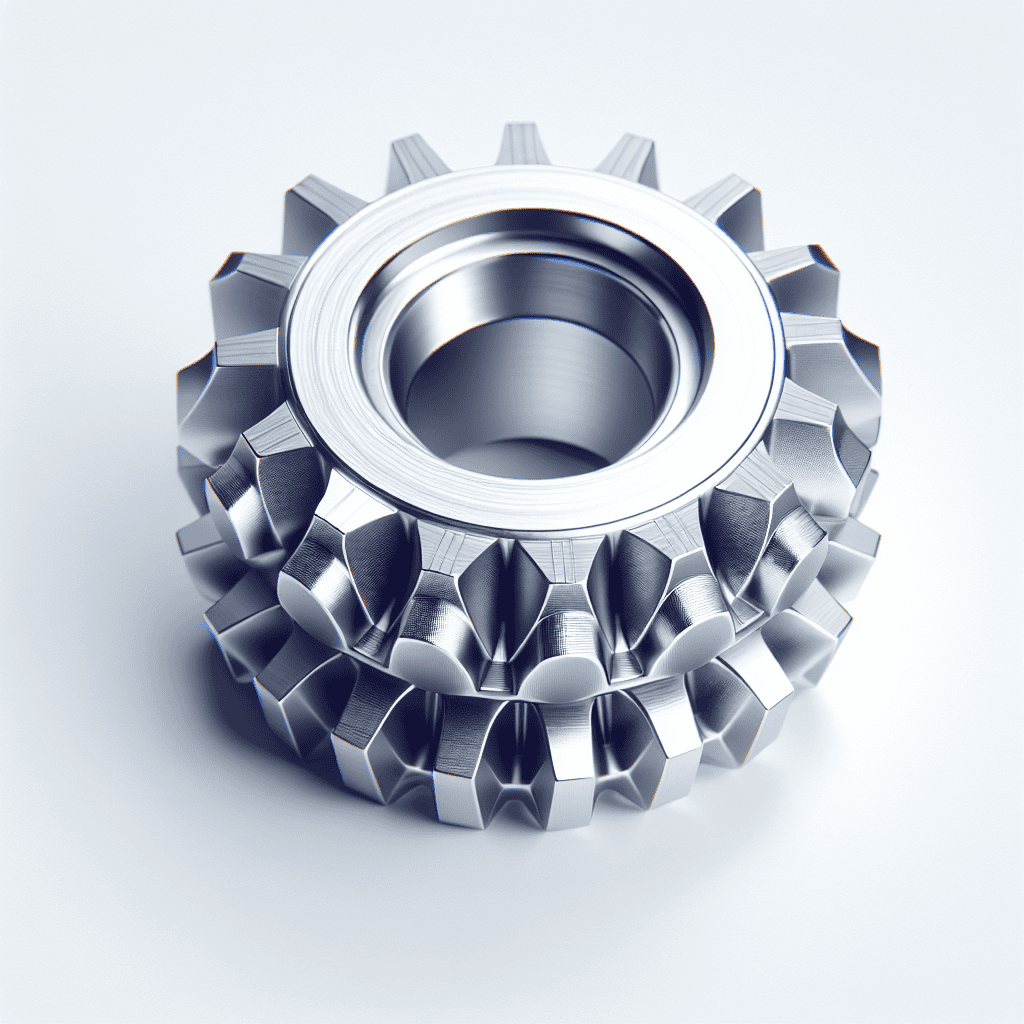

We fabricate complex medium to heavy parts like housings, rotary joints, gears, sprockets, pins, booms and sticks for hydraulic excavators and front-end loaders. Cast ductile iron and fabricated steel weldments allow configuring sturdy structural frames. We achieve robust transmission elements like shafts, gears etc. in alloy steels through casting and machining.

The operation of CNC milling machine .The CNC milling machine chamfering the mold part with chamfer tool . Off-Highway Dump Trucks

For high load bearing off-highway mining and construction trucks, we manufacture large fabricated or steel cast yaw decks, transmission cases besides intricate parts like idler gears using our heavy duty CNC machining capabilities. Ductile iron and steel cast wheels, hubs and drums are produced using our automated molding lines.

The operation of CNC milling machine .The CNC milling machine chamfering the mold part with chamfer tool . Concrete Equipment

Leveraging our casting expertise in ferrous and non-ferrous metals with CNC machining strengths, we manufacture metal components for concrete mixers, pumps, batching plants etc. This includes fabricating mixing drums, water tanks, covers, pulleys and sprockets besides structural frames, plates and liners.

accent heading

Call to action heading

- A great selling point goes here

- A great selling point goes here

- A great selling point goes here

These are the terms of the opt-in form.

Versatile Metal Manufacturing Services for Construction

Product Showcase

Kellyder possesses multifaceted capabilities to produce different types of metal parts for the building and infrastructure sectors.

Explore More Industries We Serve

Kellyder Supports Applications

Besides construction, our casting, machining and finishing expertise serves metal product needs of various other key industries.

Agriculture Equipment

We possess expertise to produce metal parts for tractors and harvesting combines including hitch categories, hay tools, planting and tillage equipment, precision farming machinery etc. This covers cast and fabricated chassis, gearbox housings etc.

Mining Equipment

Our range of mining sector solutions encompasses components for materials handling (buckets, conveyors, bins etc.), hydraulics, power transmission (gearboxes, pulleys) and machinery structurals (crawler tracks, frames, booms etc.).

Medical Products

From large CT scanner and MRI machine metal frames to small instrument handles and tiny orthopedic implants, we deliver full spectrum medical device fabrication solutions in stainless steels, titanium alloys and aluminum alloys.

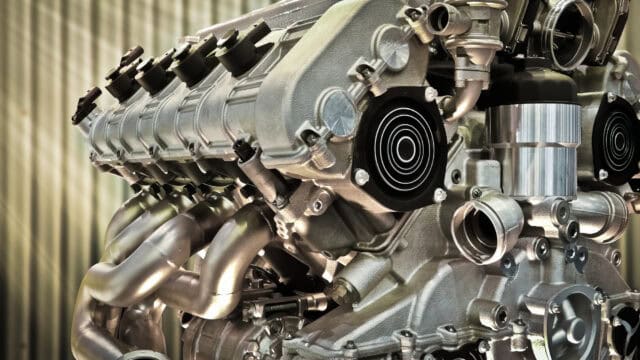

Automotive

We possess rich expertise in developing metal vehicle components encompassing transmission gears, axles, couplings, turbocharger parts, actuators and housings besides high volume exterior and structural parts.

Guides on Manufacturing

Access more information on our manufacturing capabilities through white papers, ebooks and blog posts.

Get a Free Instant Quote Now

Contact Us Today

Our experts are online 24h, will respond quickly within two hours of receiving your demand, and immediately customize personalized one-stop solutions for you according to the information and drawings you provide.