Trusted Medical Device Manufacturing Partner

Kellyder specializes in precision CNC machining and metal casting solutions for medical OEMs and innovators. With over 10 years of experience serving the medical industry, we are your trusted manufacturing partner.

Why Choose Kellyder

Our Medical Manufacturing Advantages

We stand out in medical device manufacturing with our expertise, capabilities, and commitment to quality.

Material and Experience

We have manufactured 100+ medical device projects utilizing materials like stainless steel, titanium, PEEK, and coatings like parylene. Our experience with machining, metal finishing, laser marking, clean room assembly etc. enable us to support your project seamlessly.

Supply Chain Security

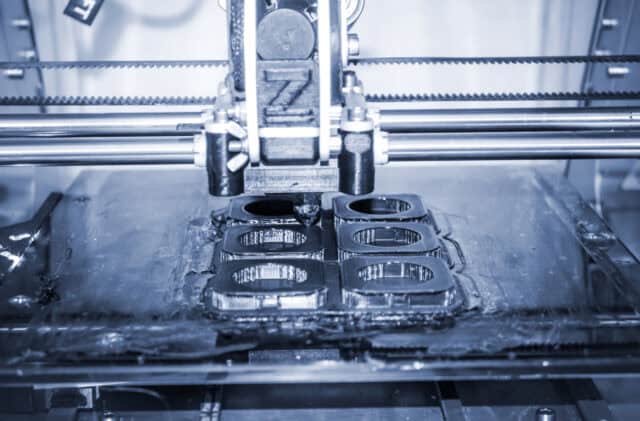

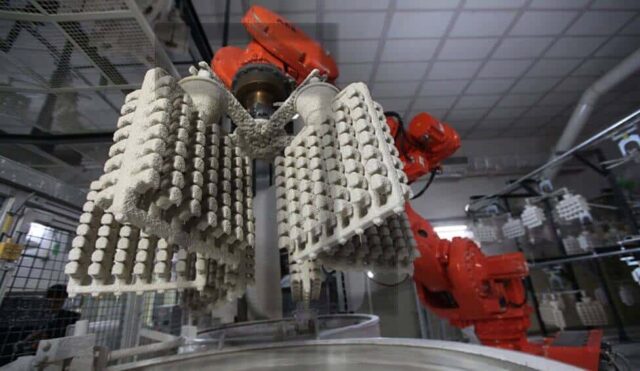

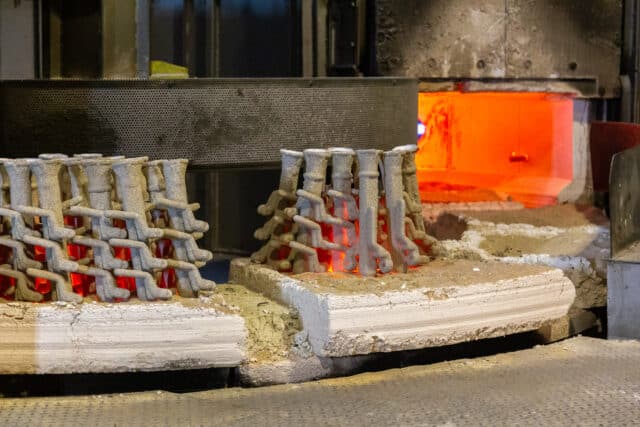

Our operations are based in China with site capabilities like CNC Machining, metal 3D printing, EDM services etc. We have partnerships with trusted supply chain vendors to deliver your medical product prototypes and volume production runs effectively.

Rapid Prototyping

Our advanced equipment and streamlined processes facilitate accelerated product development cycles. We collaborate closely to help you refine medical device prototypes swiftly and move to clinical evaluations.

Our Process for Medical Device Manufacturing Support

We utilize a streamlined and collaborative 4 step process to deliver your custom medical components efficiently.

Product Design and Development

Development and Pilot Runs

Qualification and Certification

Volume Manufacturing and Supply

Our automated cells, CNC machining centers, metal 3D printers and secondary process stations ensure consistent high quality output. Statistical process controls combined with continuous improvement projects enable us to manage key critical to quality characteristics. Our supply chain partnerships facilitate dependable delivery globally.

Medical Device Manufacturing Capability

Kellyder has integrated metalworking and 3D printing capabilities as well as finishing processes to provide complete medical device manufacturing solutions.

Send Your Request to Our Experts

Get in touch with our experts to analyze your project and customize an exclusive solution.

Send Email

Specialized Materials for Medical Device Manufacturing

- Stainless Steel (316/304)

- Stainless Steel (316/304)

Critical Device Surface Processing Techniques

| Image | Name | Description |

|

|

Passivation | Required surface treatment to render stainless steel corrosion resistant for implants. Nitric acid removes free iron and enriches chromium oxide layer. |

|

|

Electropolishing | Electrolytic polishing process to smooth stainless steel and titanium surfaces for seamless insertion/extraction of devices. Produces consistent glossy mirror finish. |

|

|

Anodizing | Anodizing builds up a thick non-conductive oxide layer on titanium surface for electrical isolation needs like pacemaker casings and for color coding. |

|

|

Parylene Conformal Coating | Biocompatible transparent parylene coatings are applied via vapor deposition to add lubricity, electrical insulation and moisture/chemical barrier for printed circuit boards and other assemblies. |

|

|

Gamma Sterilization | Terminal gamma radiation sterilization services offered through partner facilities to achieve 10−6 sterility assurance levels for packaged components. |

.wpDataTables.wpDataTablesWrapper.wdtVerticalScroll { overflow-y:auto; height:600px; }

.wpDataTableContainerSimpleTable .wdt-res-wrapper.active {overflow: initial; max-height:600px !important; }

.wpdt-fs-000018 { font-size: 18px !important;}

.wpdt-fs-000014 { font-size: 14px !important;}

/* th background color */

.wpdt-c.wpDataTablesWrapper table.wpdtSimpleTable.bt[data-has-header=’1′] td.wpdt-header-classes,

.wpdt-c.wpDataTablesWrapper table.wpdtSimpleTable thead th,

.wpdt-c .wpDataTablesWrapper table.wpDataTable thead th,

.wpdt-c .wpDataTablesWrapper table.wpDataTable thead th.sorting {

background-color: #000000 !important;

background-image: none !important;

}

| Name | Description |

|---|---|

| Passivation | Required surface treatment to render stainless steel corrosion resistant for implants. Nitric acid removes free iron and enriches chromium oxide layer. |

| Electropolishing | Electrolytic polishing process to smooth stainless steel and titanium surfaces for seamless insertion/extraction of devices. Produces consistent glossy mirror finish. |

| Anodizing | Anodizing builds up a thick non-conductive oxide layer on titanium surface for electrical isolation needs like pacemaker casings and for color coding. |

| Parylene Conformal Coating | Biocompatible transparent parylene coatings are applied via vapor deposition to add lubricity, electrical insulation and moisture/chemical barrier for printed circuit boards and other assemblies. |

| Gamma Sterilization | Terminal gamma radiation sterilization services offered through partner facilities to achieve 10−6 sterility assurance levels for packaged components. |

Trusted for Various Medical Device Projects

Kellyder leverages its manufacturing expertise to serve various medical OEMs and contract manufacturers.

The operation of CNC milling machine .The CNC milling machine chamfering the mold part with chamfer tool . Orthopedic Implants

The operation of CNC milling machine .The CNC milling machine chamfering the mold part with chamfer tool . Surgical Power Tools

The operation of CNC milling machine .The CNC milling machine chamfering the mold part with chamfer tool . Laparoscopy Instruments

accent heading

Call to action heading

- A great selling point goes here

- A great selling point goes here

- A great selling point goes here

These are the terms of the opt-in form.

Trust Our Expert Craftsmanship and Quality

Our Product Cases

View a select sample of our manufacturing capabilities applied to medical device projects.

Explore More Industries We Serve

Kellyder Supports Applications

Our CNC machining, metal printing, precision casting and finishing capabilities serve varied product development needs.

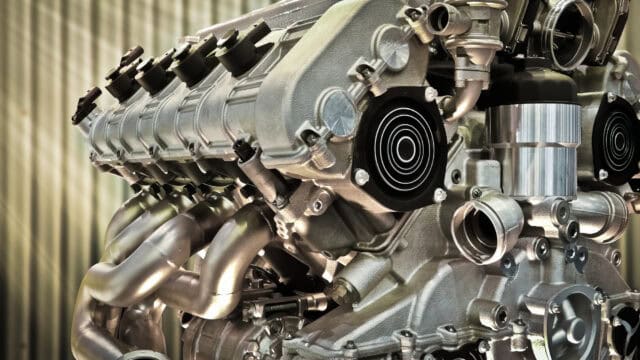

Automotive

Auto part prototypes and volume production including aluminum casting, machining of steel and plastic components like sensors, connectors, turbochargers etc.

Aerospace

Aircraft component fabrication including titanium and aluminum machining, 3D printing, investment casting etc. for high quality standards.

Industrial Automation

Rigorous contract manufacturing services for mechanical automation sectors including robotics, press tools and other precision equipment.

Construction Equipment

Heavy duty fabricated buckets, wear-resistant components, attachments etc. suit excavators and backhoes working in abrasive environments. We also produce hydraulic and powertrain elements for reliability.

Guides on Manufacturing

Access more information on our manufacturing capabilities through white papers, ebooks and blog posts.

Get a Free Instant Quote Now

Contact Us Today

Our experts are online 24h, will respond quickly within two hours of receiving your demand, and immediately customize personalized one-stop solutions for you according to the information and drawings you provide.