CNC Turning Services by Kellyder

Kellyder, headquartered in China, is your premier partner for CNC Turning, offering tailored solutions for both intricate components and high-volume production.

- High Precision: Our meticulous approach guarantees unmatched precision in every component.

- Competitive Pricing: We deliver cost-effective solutions while maintaining high-quality standards.

- Rapid Turnaround: Our efficient processes ensure timely delivery to meet your schedules.

- ISO 9001 Quality Assurance: Our commitment to quality is backed by ISO 9001 certification, ensuring consistent excellence in all our offerings.

24h

Quick Quote±0.02

mm Tolerance20%

Savings

Understanding CNC Turning Service

Key Features of CNC Turning:

- Precision and Complexity: CNC turning is renowned for its precision and capability to produce complex parts. The computer-controlled process allows for exact dimensions and complex geometries.

- Material Versatility: This process is compatible with a wide range of materials, including metals like aluminum and steel, and plastics such as PP and ABS. This versatility makes it ideal for various industries and applications.

- Efficiency: CNC turning is an automated process, meaning it can produce parts quickly and consistently, making it suitable for both prototype development and large-scale production.

- Customization: It offers high levels of customization. Parts can be tailored to specific dimensions and shapes as per the requirements, providing flexibility in design and production.

CNC Turning Tolerances & Standards

Dimensional Tolerances for Size and Position

Applicable Features: Includes length, width, height, and diameter dimensions, along with positional aspects like concentricity and symmetry. Standard Tolerance: ±0.005 inches for both dimensional accuracy and positional precision.

Tolerances for Orientation and Form

Lengths up to 12 Inches: Tolerance of ±0.005 inches, with an angular deviation allowance of 1/2 degree. Lengths exceeding 24 Inches: For these dimensions, refer to the Xometry Manufacturing Standards for specific tolerances.

Edge Conditioning Standards

Default Treatment: Sharp edges will be systematically deburred and softened. Special Requirements: If certain edges need to remain sharp for critical applications, this requirement should be explicitly indicated on the technical drawings or specifications.

Kellyder's Diverse Range of CNC Materials

- Aluminum

- Brass

- Stainless Steel

- Aluminum

Aluminum

Learn MoreKnown for its lightweight and corrosion resistance, ideal for a wide range of applications.

- Brass

Brass

Learn MoreOffers excellent machinability and is commonly used for decorative purposes and electrical components.

- Stainless Steel

Stainless Steel

Learn MoreRenowned for its corrosion resistance and strength, perfect for parts that require durability and longevity.

CNC Turning Surface Finishes

Flawless Finish

Our CNC turning services provide superior surface finishes, enhancing the aesthetic and functional quality of your parts.

| Name | Description |

|---|---|

| Standard (As-Milled) | Quick turnaround, visible tool marks, optional edge and burr removal. Comparable to 125 uin Ra finish. |

| Bead Blast | Smooth, matte surface |

| Tumbled | Removes edges and burrs, may reduce machine marks on exterior surfaces. |

| Anodized (Type II and III) | Type II: Corrosion-resistant, available in various colors, commonly for aluminum. Type III: Thicker, wear-resistant layer plus corrosion resistance. |

| Titanium Anodize | Increases fatigue strength and wear resistance, common in aerospace and medical devices. |

| PTFE Impregnated Hard Anodize | Self-lubricating, wear-resistant surface for aluminum or titanium. |

| Chem Film (Chromate Conversion Coating) | Corrosion resistance, good conductivity, minimal thickness increase. |

| As Machined | Standard machining finish (Ra 3.2μm / Ra 126μin) |

| Smooth Machining | Smoother than standard (Ra 1.6μm / Ra 63μin) |

| Fine Machining | Finer finish for precision parts (Ra 0.8μm / Ra 32μin) |

| Polishing | Polished surface (Ra 0.8μm / Ra 32μin) |

| Brushed | Brushed texture (Ra 1.2μm / Ra 47μin) |

| Powder Coated | Durable protective layer |

| Black Oxide | Black finish |

| Electroless Nickel Plating | Nickel-plated surface |

| Bead Blasted + Chromate Conversion Coating | Combination of bead blasting and chromate conversion |

| Bead Blasted + Anodized Type III | Bead blasting with hardcoat anodizing |

| Bead Blasted + Anodized Type II | Bead blasting with glossy or matte anodizing |

| As Machined + Anodized Type II/III | Standard machining with Type II or III anodizing |

| Brushed + Electropolished | Brushed finish with electropolishing |

| Chromate Conversion Coating | Applied for corrosion resistance |

Get a Free Instant Quote

We will respond quickly to your needs within two hours and instantly customize a solution for you based on the information and drawings you provide.

Quote Now

Why Choose Kellyder CNC Turning Services

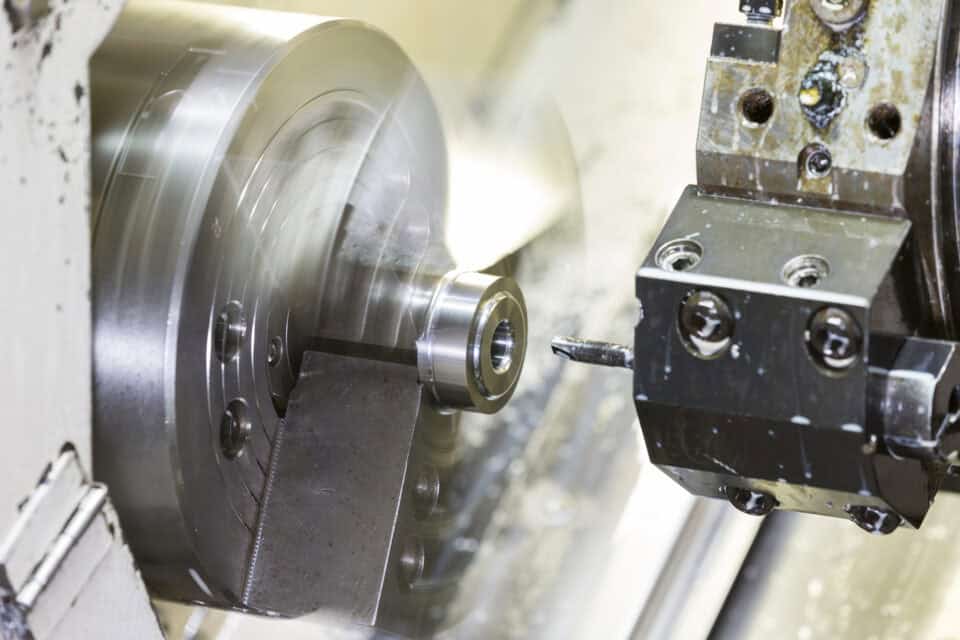

Unlocking Efficiency with CNC Turning

Precision in Every Turn

CNC turning is a cornerstone of precision manufacturing, vital for producing components with intricate geometries and exacting tolerances.

This process excels in creating cylindrical parts where precision, symmetry, and speed are paramount.

Advancements in CNC turning technology allow for greater flexibility and efficiency, facilitating the creation of complex designs that are beyond the scope of conventional machining.

Opting for CNC turning means choosing a path to superior quality, consistency, and cost-effectiveness in your manufacturing processes.

Why Kellyder Stands Out in CNC Turning

Tailored Excellence at Kellyder

Choosing Kellyder for CNC turning services means entrusting your projects to a leader in innovation and precision.

Our state-of-the-art CNC turning centers are equipped with advanced features, including multitasking capabilities and automated systems, ensuring impeccable accuracy and reduced turnaround times.

At Kellyder, we don’t just manufacture parts; we engineer solutions that meet the specific needs of our clients, backed by a commitment to quality and customer satisfaction.

Our expertise in handling a diverse range of materials and complex requirements sets us apart, making Kellyder the preferred choice for CNC turning services.

Get a Free Instant Quote Now

Contact Us Today

Our experts are online 24h, will respond quickly within two hours of receiving your demand, and immediately customize personalized one-stop solutions for you according to the information and drawings you provide.