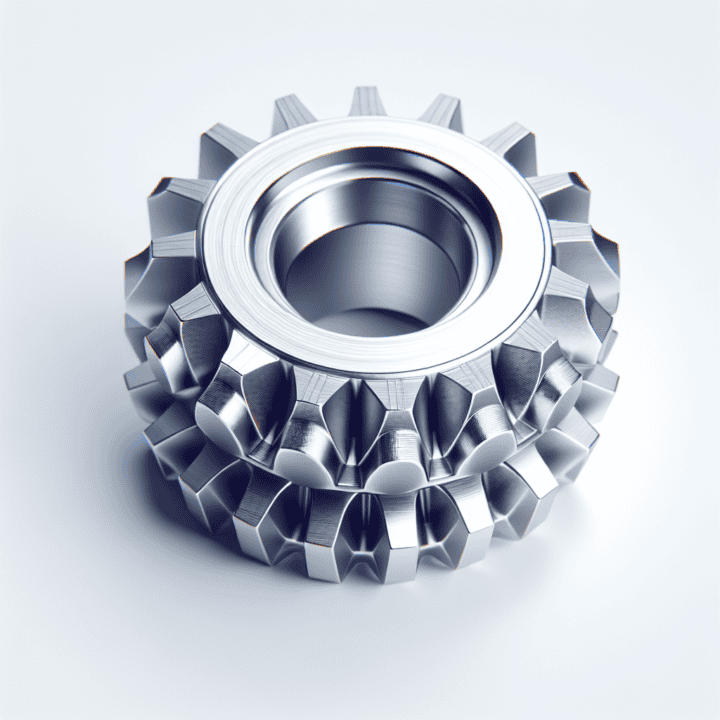

CNC Milling Service

24h

Quick Quote±0.01

mm Tolerance20%

Savings

Kellyder Custom CNC Milling Service

Our CNC Milling Tolerances

Dimensions from 120mm up to 400mm

±0.2mm

Dimensions from 400mm to 1000mm

±0.3mm

Dimensions from 1000mm to 2000mm

±0.5mm

CNC Milling Materials

- Aluminum Alloys

- Copper & Bronze & Brass

- Stainless Steel

- Zinc

- Aluminum Alloys

Aluminum Alloys

Learn More- Aluminum 6061

- Aluminum 5052

- Aluminum 2024

- Aluminum 6063

- Aluminum 7050

- Aluminum 7075

- Aluminum MIC-6

- Copper & Bronze & Brass

Copper & Bronze & Brass

Learn MoreCopper

- Copper 101

- Copper C110

Bronze

- Copper C932

Brass

- Copper 260

- Copper 360

- Stainless Steel

Stainless Steel

Learn More- Nitronic 60 (218 SS)

- Stainless Steel 15-5

- Stainless Steel 17-4

- Stainless Steel 18-8

- Stainless Steel 303

- Stainless Steel 316/316L

- Stainless Steel 416

- Stainless Steel 410

- Stainless Steel 420

- Stainless Steel 440C

- Zinc

CNC Milling Surface Finishes

Flawless Finish

Our CNC milling services provide superior surface finishes, enhancing the aesthetic and functional quality of your parts.

| Name | Description |

|---|---|

| Standard (As-Milled) | Quick turnaround, visible tool marks, optional edge and burr removal. Comparable to 125 uin Ra finish. |

| Bead Blast | Smooth, matte surface |

| Tumbled | Removes edges and burrs, may reduce machine marks on exterior surfaces. |

| Anodized (Type II and III) | Type II: Corrosion-resistant, available in various colors, commonly for aluminum. Type III: Thicker, wear-resistant layer plus corrosion resistance. |

| Titanium Anodize | Increases fatigue strength and wear resistance, common in aerospace and medical devices. |

| PTFE Impregnated Hard Anodize | Self-lubricating, wear-resistant surface for aluminum or titanium. |

| Chem Film (Chromate Conversion Coating) | Corrosion resistance, good conductivity, minimal thickness increase. |

| As Machined | Standard machining finish (Ra 3.2μm / Ra 126μin) |

| Smooth Machining | Smoother than standard (Ra 1.6μm / Ra 63μin) |

| Fine Machining | Finer finish for precision parts (Ra 0.8μm / Ra 32μin) |

| Polishing | Polished surface (Ra 0.8μm / Ra 32μin) |

| Brushed | Brushed texture (Ra 1.2μm / Ra 47μin) |

| Powder Coated | Durable protective layer |

| Black Oxide | Black finish |

| Electroless Nickel Plating | Nickel-plated surface |

| Bead Blasted + Chromate Conversion Coating | Combination of bead blasting and chromate conversion |

| Bead Blasted + Anodized Type III | Bead blasting with hardcoat anodizing |

| Bead Blasted + Anodized Type II | Bead blasting with glossy or matte anodizing |

| As Machined + Anodized Type II/III | Standard machining with Type II or III anodizing |

| Brushed + Electropolished | Brushed finish with electropolishing |

| Chromate Conversion Coating | Applied for corrosion resistance |

Get a Free Instant Quote

We will respond quickly to your needs within two hours and instantly customize a solution for you based on the information and drawings you provide.

Quote Now

The Cutting Edge of CNC Milling

Advantages of CNC Milling

Unmatched Accuracy and Efficiency in Metal Shaping

Types of CNC Milling

Different Choose

Vertical CNC Mills: These mills have a vertical spindle axis. This means that the cutters that perform the milling operations are held vertically in the spindle and rotate on the spindle’s axis.

Vertical mills are typically used for parts that can be mounted on a single side.

Horizontal CNC Mills: In these mills, the spindle axis is oriented horizontally. Horizontal mills are generally used for larger and heavier parts.

Turret Mills: Turret mills are versatile vertical mills that allow the spindle to move vertically along the column. This type of mill is good for smaller operations.

Bed Mills: A type of vertical mill, bed mills have a spindle that moves perpendicular to the bed of the mill.

CNC Milling Machines with a Rotary Table: These milling machines are equipped with a rotary table that allows milling at various angles; this feature is ideal for tools like drill bits or reamers.

Multi-Axis CNC Mills: These mills can operate in several planes (usually 3, 4, or 5-axis mills), allowing for advanced and complex machining.

Get a Free Instant Quote Now

Contact Us Today

Our experts are online 24h, will respond quickly within two hours of receiving your demand, and immediately customize personalized one-stop solutions for you according to the information and drawings you provide.