Custom Metalworking Service Supplier

Awesome and catchy heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Comprehensive Metalworking

As an ISO 9001 certified manufacturer with over 20 years of experience, we provide an unrivaled breadth of metalworking services spanning sand casting, investment casting, die casting, CNC machining, and more - ready to meet wide-ranging requirements.

Trusted Delivery and Quality

Since starting operations in 2011, we have built trusted partnerships with customers in industries like automotive, aerospace, and agriculture by consistently delivering high quality parts on time via robust processes.

Customized Support and Guidance

Tell us exactly what you need and we'll suggest suitable materials, processes, timelines, and design optimizations to meet your specific requirements, drawing on our extensive expertise to provide tailored guidance and solutions.

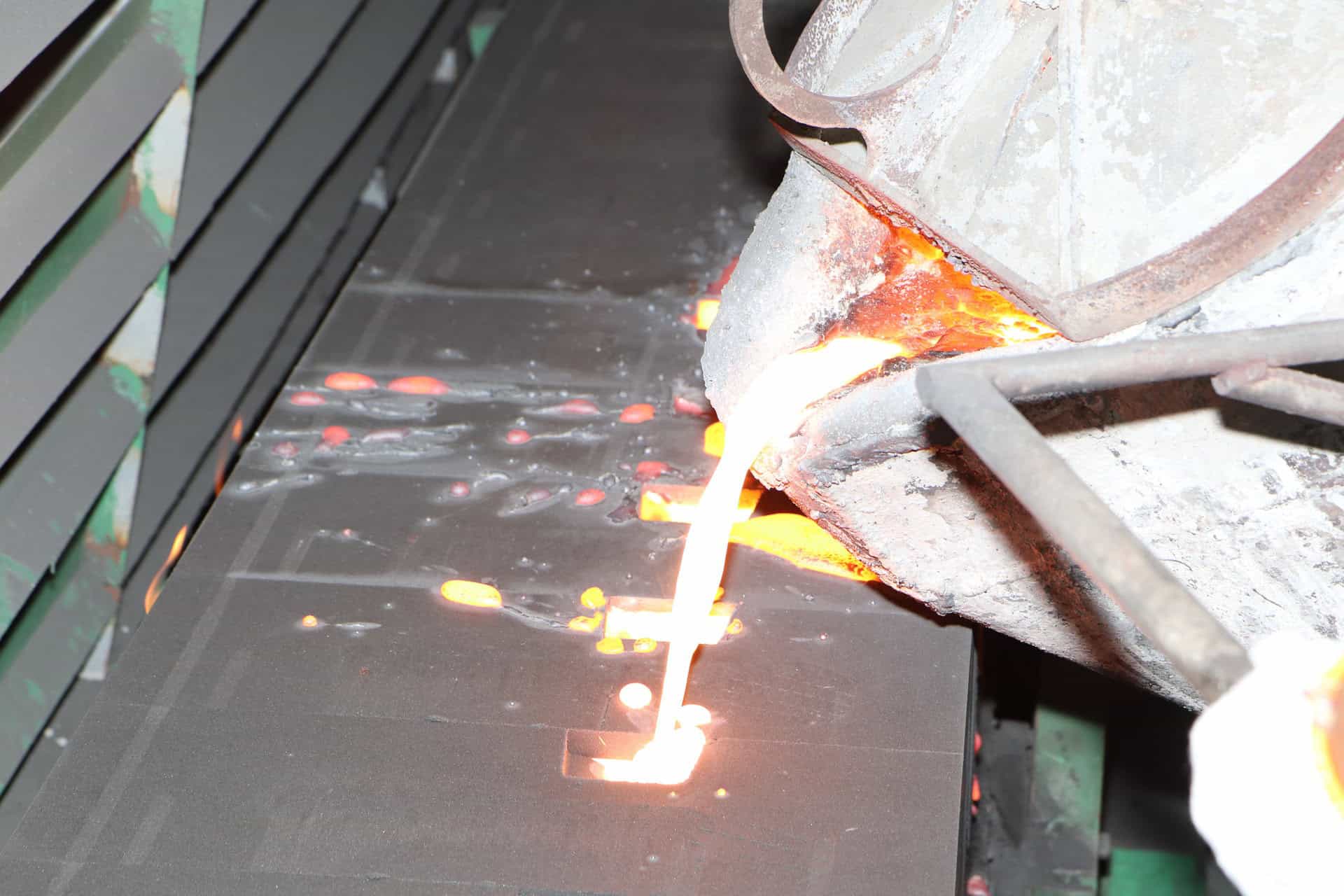

Comprehensive Metalworking

As an ISO 9001 certified manufacturer with over 20 years of experience, we provide an unrivaled breadth of metalworking services spanning sand casting, investment casting, die casting, CNC machining, and more - ready to meet wide-ranging requirements.

Trusted Delivery and Quality

Since starting operations in 2011, we have built trusted partnerships with customers in industries like automotive, aerospace, and agriculture by consistently delivering high quality parts on time via robust processes.

Customized Support and Guidance

Tell us exactly what you need and we'll suggest suitable materials, processes, timelines, and design optimizations to meet your specific requirements, drawing on our extensive expertise to provide tailored guidance and solutions.

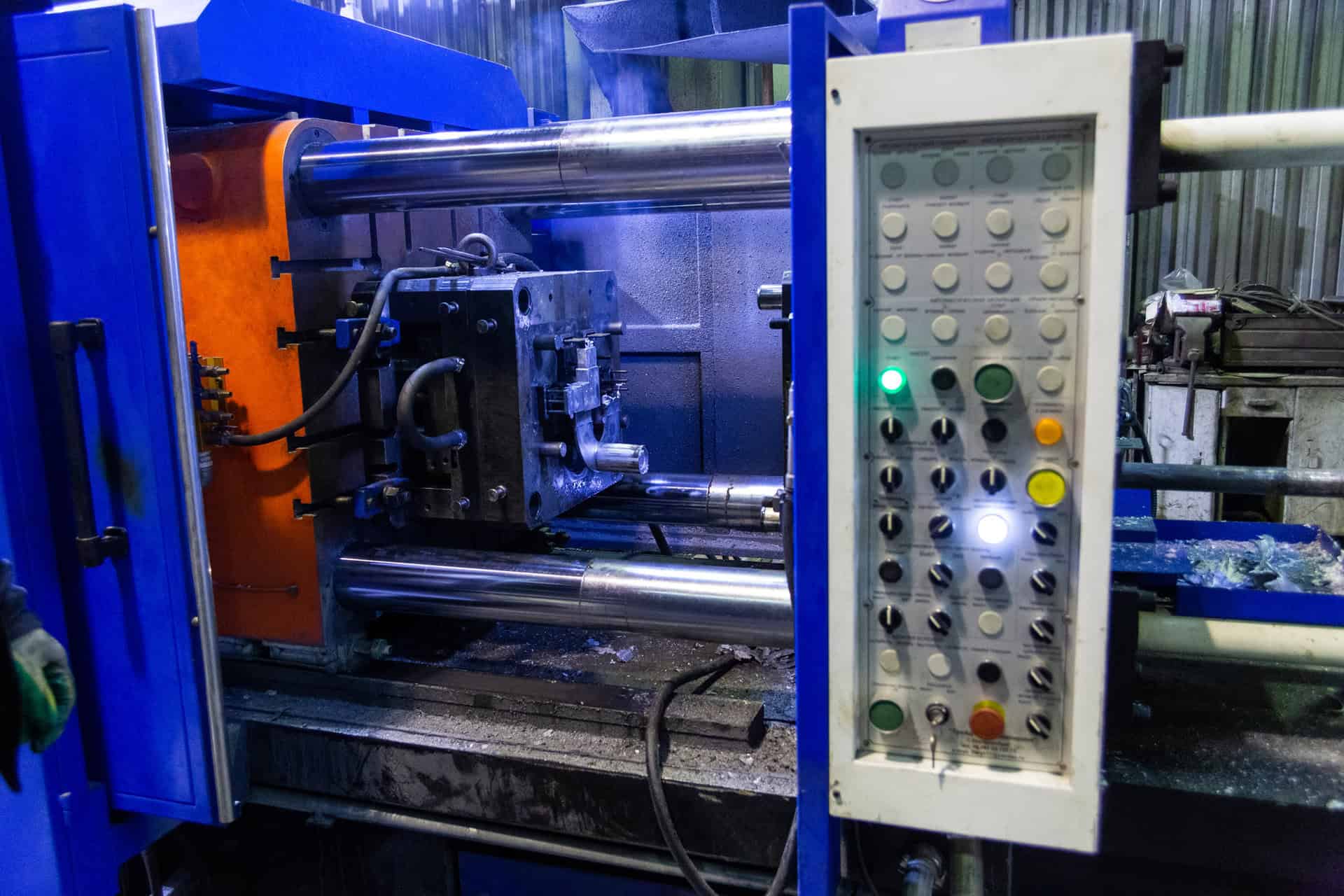

Broad Capabilities

We offer comprehensive metalworking services for prototyping or volume production. Our extensive equipment includes die casting machines from 100-800 tons and CNC machining centers.

Decades of Expertise

Since starting in 2011, we've built trusted partnerships with customers by delivering on our commitments for quality, delivery, and service.

Customized Support

Tell us what you need and we'll suggest suitable materials, processes, timelines, and more to meet your specific requirements.

Expert in the Metal Working Industry

Metalworking Services

Section heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Why Choose Kellyder

We offer key advantages making us the ideal manufacturing partner for quality-focused clients requiring high precision metal components.

Streamlined for Savings

Thanks to professional engineering expertise optimizing manufacturability and streamlined, repeatable production processes, Kellyder maintains a unit pricing advantage averaging 20% lower than alternative suppliers. That makes us very cost competitive without ever compromising on quality or delivery.

Stringent Standards

Multiple quality control checks throughout our manufacturing processes ensure finished parts consistently meet your exact specifications. ISO 9001 certification further validates our uncompromising quality standards and rigorous quality procedures. You can have confidence that Kellyder will deliver.

Technical Capabilities

With seasoned engineering teams and operators with decades of experience, Kellyder offers in-depth knowledge and specialized skills spanning metallurgy, casting process engineering, CNC programming, machining techniques, quality control procedures, and more.

Our Strong Supply Chain

We provide complete solutions spanning activities before and after our precision casting and machining operations through collaboration with supply chain partners worldwide.

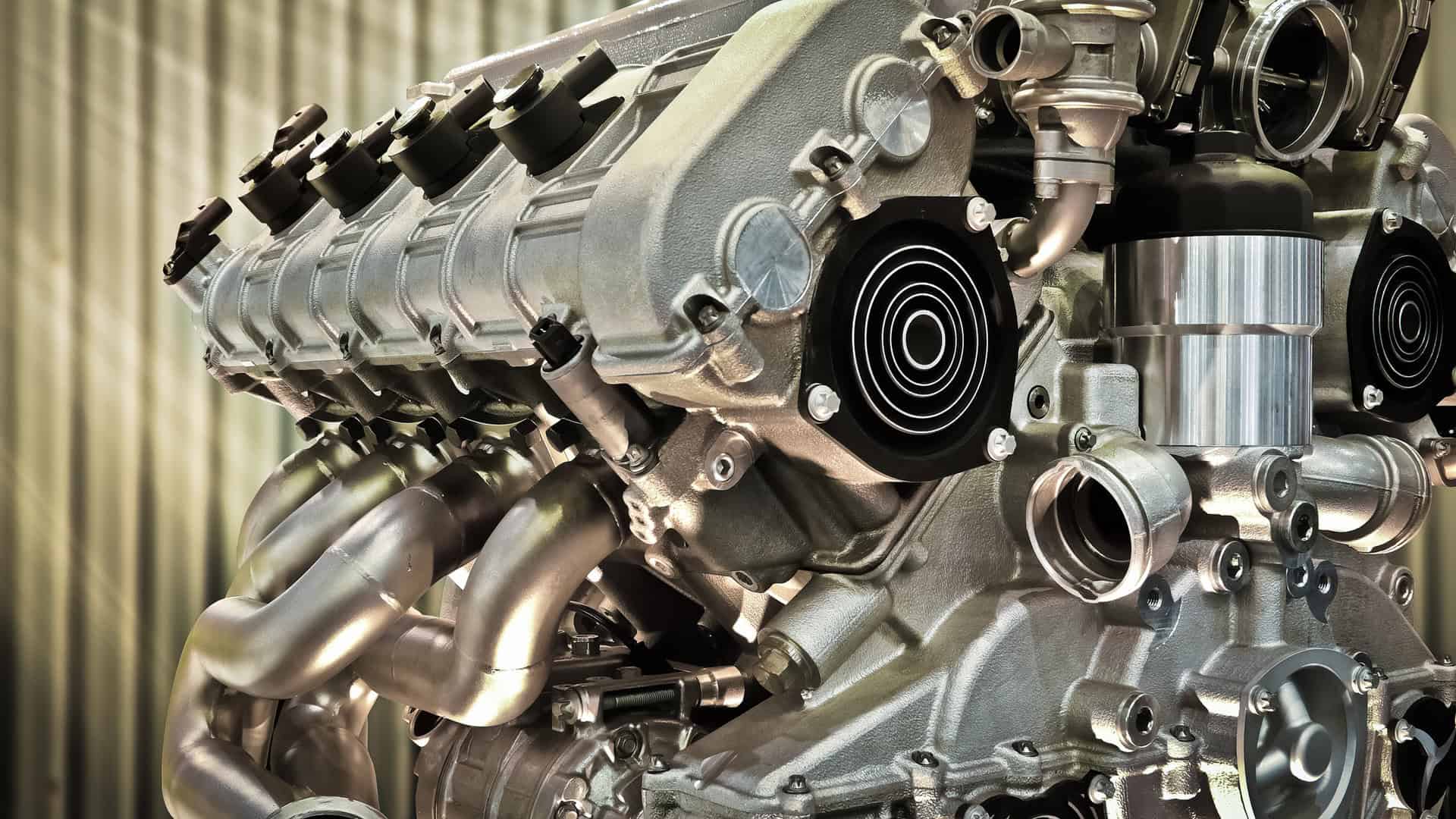

See Our Product Cases

We provide cast and machined components to a range of industries and applications. Here are some examples of parts we manufacture.

I am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your textI am a heading

Here goes your text

Discuss Your Needs

Engage with your account representative to discuss specifications and submit drawings, annual volumes, target pricing, performance needs, operating conditions, delivery timeline, regulations, and other critical details for a comprehensive understanding of your expectations.

Engineering Collaboration

Dedicated engineers review manufacturability using DFMA practices, perform tolerance stack analyses, optimize draft angles (target 2 degrees+) and wall thicknesses (as low as 2mm), develop prototypes via 3D printing, and otherwise ready parts for production over a 2 week timeline.

Procurement Formalization

Your account manager develops final quotation with target 10% savings off preliminary quote by value engineering. Payment terms at 30% deposit, 60% before shipment, final 10% after final inspection (within 30 days of order receipt).

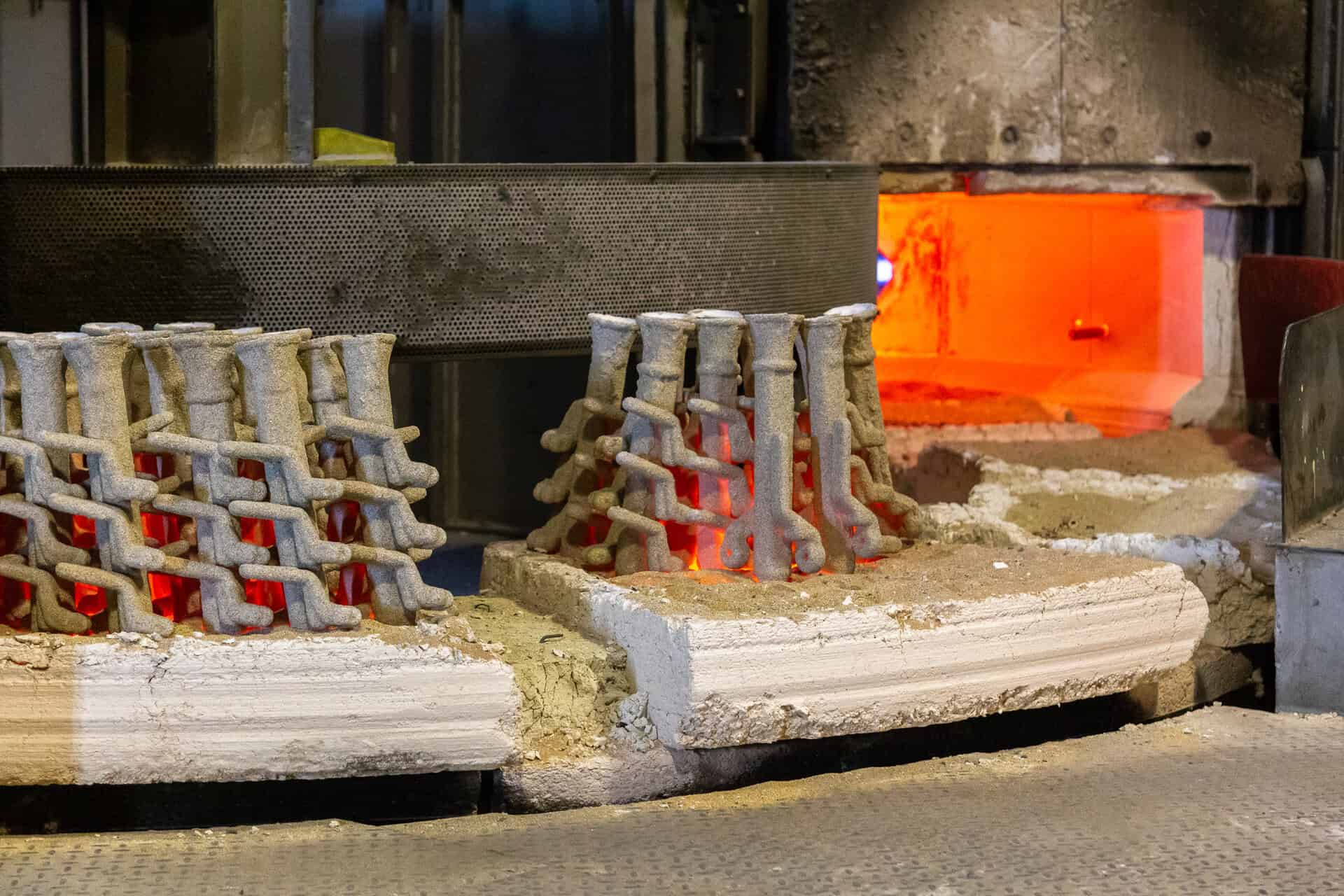

Specialized Production

Leveraging approved CAD models, our experts execute production orders through casting (delivered in as few as 15 days from tooling completion), CNC machining (5 day avg lead time), cleaning (automated 16 station units), and intermediate quality assurance steps.

Post-Processing & Surface Treatments

Parts undergo any final finishing steps you specify - whether powder coating (avg 5 day lead time), plating (7 day avg lead time), passivation, chromating, or other processes guaranteeing satisfaction upon final inspections.

On-Time Global Logistics

Your dedicated logistics specialist manages secure packaging, customs/duties coordination, optimal carrier selection for your location, and on-time delivery coordination with tracking notification, getting your components delivered damage free when and where they need to be.

Partner with Kellyder

Get in Touch with Our Experts

Get a Fast Free Online Quote Directly

Our Blog

Educational articles, technical developments etc in precision metalworking to assist with your initiatives.